EVERSION COMPOSITES

BACKGROUND EXPERIENCE

A collection of selected background projects are illustrated and linked below for your review.

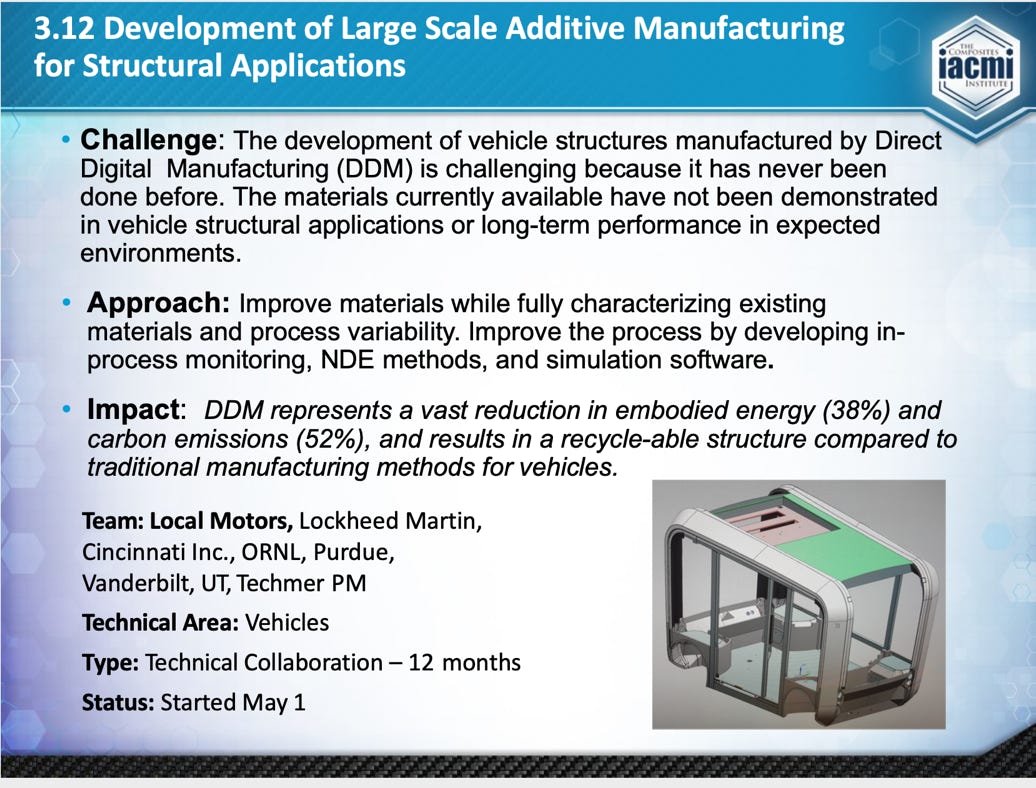

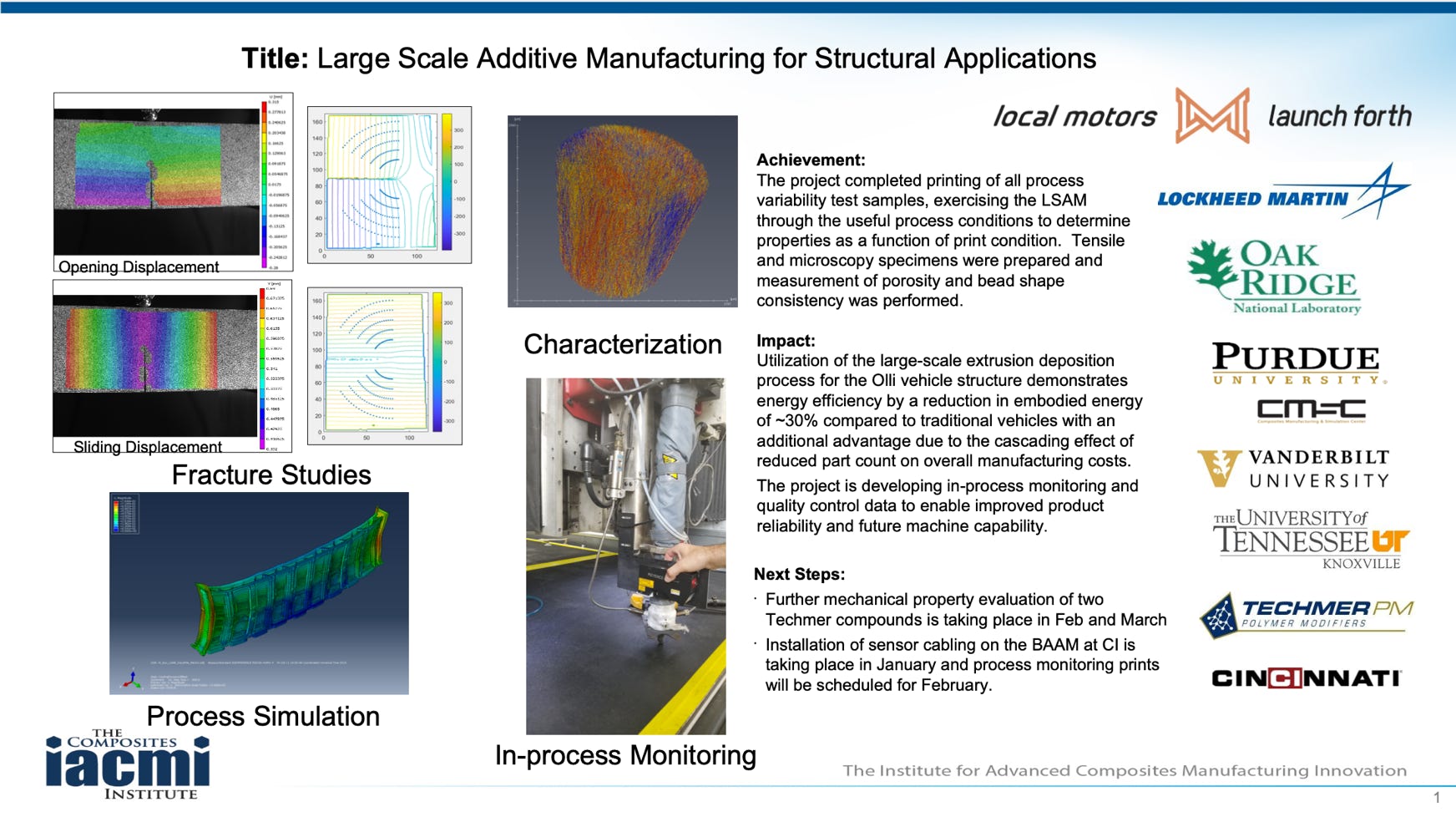

Starting in early 2015 until May 2020 I had been engaged with IACMI as principle investigator on projects 3.6 and 3.12 for Local Motors while also collaborating on project 7.7 with Purdue and Dupont. The above public release project overview and quarterly update for project 3.12 show some of the valuable efforts being performed in development of large scale extrusion deposition. I have five years of hands-on experience with BAAM and LSAM machines as well as printing with hundreds of custom compounds in collaboration with materials suppliers to optimize products for the process. As a team, we have several publications available for your review. I also participated directly in the design and development of Olli 2.0, an autonomous shuttle with a novel 3d printed structural chassis.

The Resin Infusion Rigidized Inflatable concept won an award from the NASA JSC Center Innovation Fund and a small prototype was designed and built. For spacecraft structures it allows permanently rigid shell structures to be expanded from a softgood package, infused with resin, and cured in place. It is applicable to many terrestrial applications as well such as remote housing and bridge construction where compact delivery and rapid deployment are critical performance drivers.

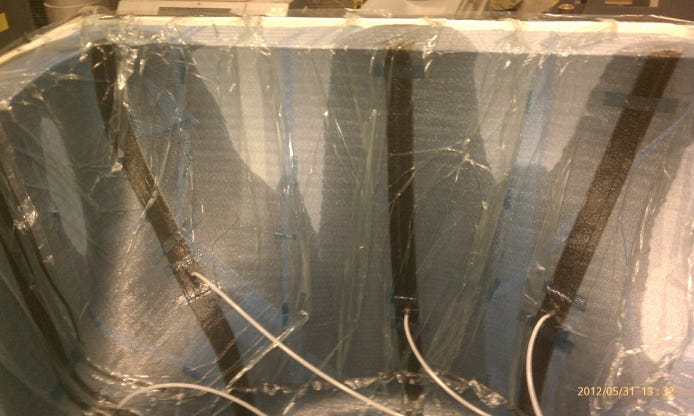

The MMSEV Composite Cabin project team designed, built, and tested a full scale cabin for the Multi-Mission Space Exploration Vehicle (manned rover). These photos show the resin infusion of the large tooling mold that we manufactured in-house. I performed permeability tests on the reinforcement stack and FEA of the infusion process to design the flow mesh patterns which resulted in a successful infusion and manufacture of the tool. The cabin part was an out of autoclave prepreg system that was oven cured with vacuum bag only.

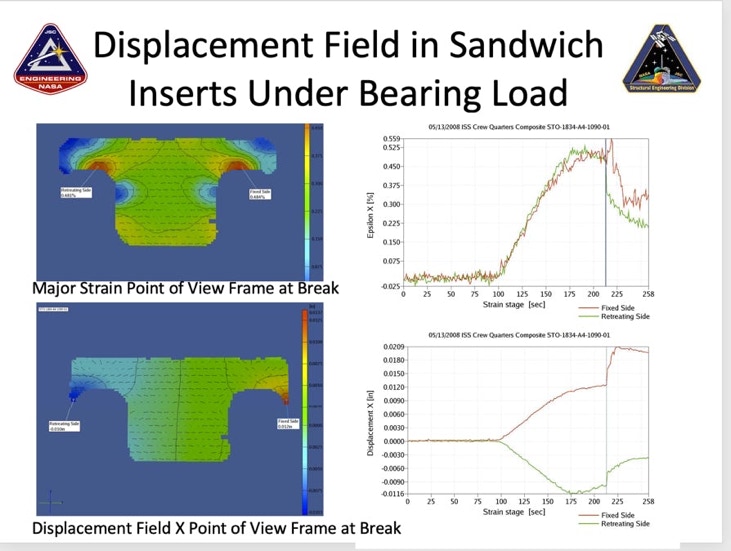

I presented results of sandwich insert testing for the ISS Crew Quarters at the Composite Materials Handbook PMC Forum. This was only a small portion of the work performed on the project as I was responsible for all materials and processes for the Crew Quarters: materials selection, specification, testing, EDRS drawing review and approvals, PDR and CDR support, MIULs and MUAs, manufacturing DRs and MRB, qualification, and certification.